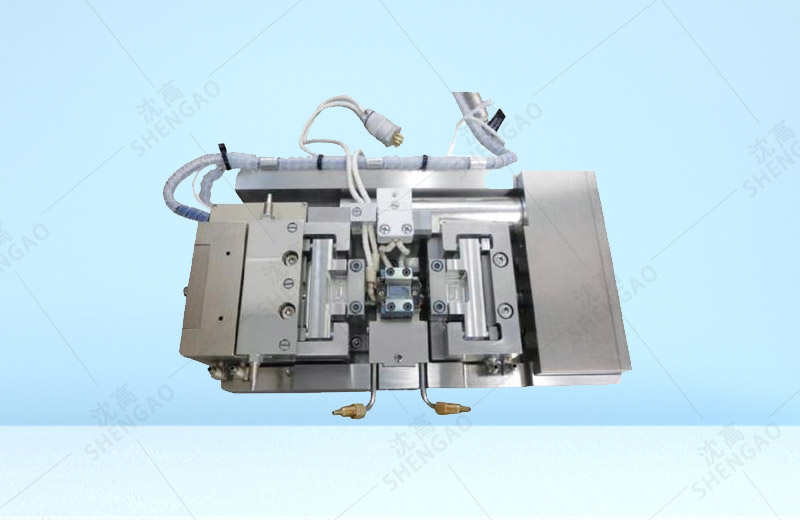

Tensile testing can be done for many materials, such as metallic materials (study of toughness process, stress-induced phase change and plastic deformation), polymer materials, ceramics, etc. Scanning electron microscopy (SEM) was used to carry out in situ imaging of the morphological changes of the microstructure, so as to understand the causes of morphological changes and image the causes of changes and the time of changes. The combination of dynamic experimental information can overcome the uncertainties in the interpretation of traditional stress/strain data. For stretching, extrusion and bending tests, we offer a wide range of devices with loads ranging from 2N to 5000N.

Main technical features:

1, large load range: 200N, 300N, 2000N and 5000N

2, replaceable weighing sensor range as small as 2N

3. Strain rate: 5μm/ min-6mm /min

4. Optional 3-point and 4-point horizontal bending accessories

5. Special accessories for EBSD samples

6, heating and water cooling platform equipped with customized jaws

7. A simple software user interface provides real-time stress-strain curves, combined with flexible thresholds for complex experiments, including cyclic loads.

8. Synchronous image and data acquisition is supported, and the sample change process can be analyzed in detail through stress and strain.

Main application fields:

1, metal and coating: for the study of grain changes, coating bonding, high temperature deformation and relaxation mechanism, grain rotation and texture changes.

2, composite materials: used to study the toughness and strength of materials

3, fiber: research material strength

4, polymer: used for the study of plastic flow and failure mechanism

5. Brittle materials: study the origin and passivation of tiny cracks

6. Geology: Study of hot compression experiments of rocks and cold deformation mechanism of ice cores