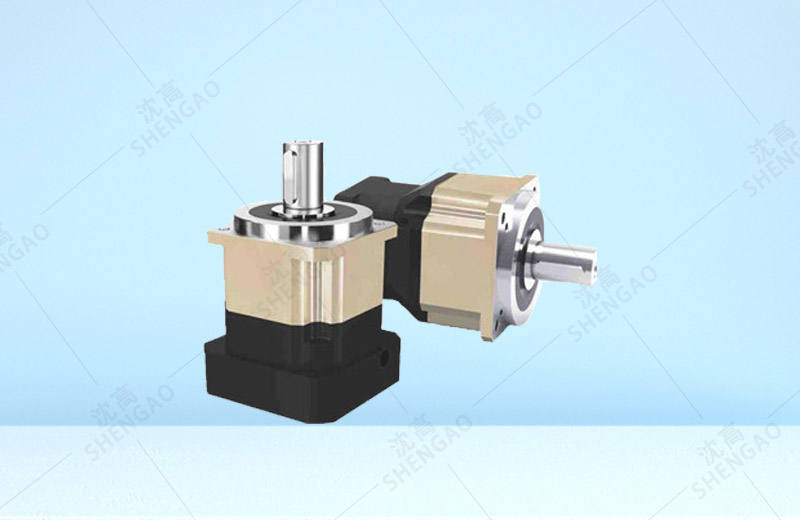

● Bevel gear transmission structure. The material is made of high quality alloy steel, which is optimized to obtain better wear resistance and impact toughness.

● The tooth surface shape and lead trimming, to reduce the impact and noise of gear meshing, increase the service life of gear system.

● Both ends of the output shaft are supported by double bearings with high precision and low clearance to achieve greater carrying capacity.

Matters needing attention when choosing the right reducer:

● Determine the reduction ratio. According to the motor speed and the need to output the speed of the ratio, as well as the mechanical moment of inertia and the motor of the ratio of the square to determine the final.

● Calculate torque. After the reduction ratio is determined, the rated torque of the selected servo motor is multiplied by the reduction ratio. In principle, the obtained value is less than the rated output torque of the similar reducer provided on the reducer product catalogue. At the same time, the overload capacity of the driving motor and the maximum working torque required in practice should also be considered. Required maximum operating torque should be less than 2 times the rated output torque.

● Select return clearance. The smaller the return clearance, the higher the accuracy and the more accurate the transmission. Lateral/radial forces and average life are also taken into account. The reducer with large transverse/radial force has high reliability in installation and use. Usually the average life of the servo motor far exceeds the life of the equipped. After meeting the above indicators, you can choose the reducer with the installation size, shaft diameter and input flange matching the motor according to the product catalogue.

● Finally, the weight of the motor should be considered. Generally, the reducer is only allowed to be matched with the motor less than a certain weight. The motor is too heavy, so it is necessary to consider the auxiliary installation method.

Application field of servo reducer:

Precision machine tools, metallurgical equipment, wind power equipment, chemical equipment, solar energy, industrial robots, conveying equipment, engineering machinery, textile equipment, rubber and plastic equipment, food machinery, daily necessities machinery, flat glass production line, packaging equipment, printing equipment, automotive production line and other high-precision applications.