QZ submersible axial flow pump main features

1) Both the impeller and guide vane models have been tested, and the pump efficiency can reach about 85%.

2) Reasonable selection of the type of punching machine, reduce the manufacturing cost, slender motor shape is conducive to improve the efficiency of the pump.

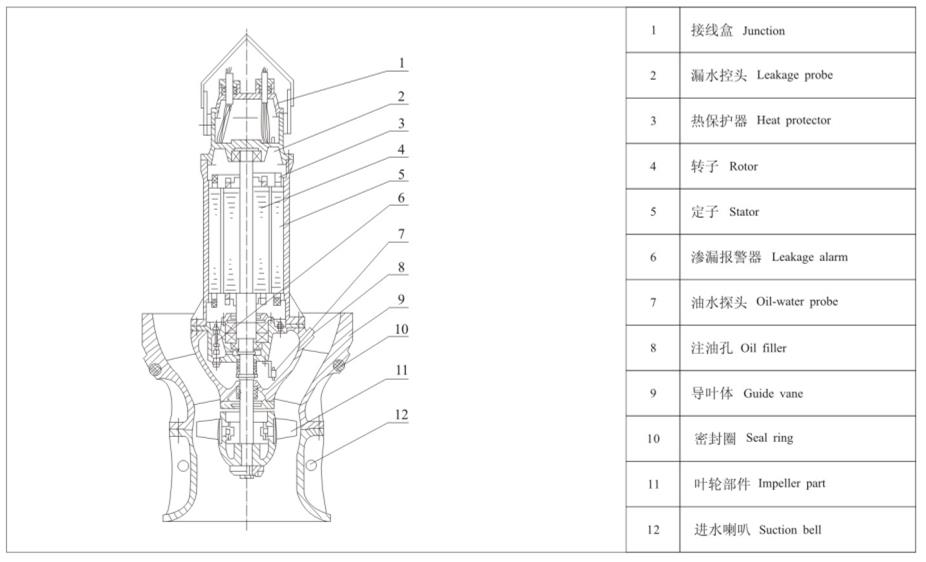

3) QZ submersible pump adopts multiple independent series rubber seal is used, ensure reliable sealing device, cable at the same time to the lateral sealing of cable, the cable and cable sheath made integration structure, so that even in the case of damaged cable outer rubber sleeve, can still maintain a good seal, effectively prevent the water into the motor chamber.

4) The junction box is completely separated from the motor chamber and sealed separately. Even if the cable is damaged, the motor chamber will not leak.

5) The stator of the motor adopts F-class insulation (1550C), and each phase is equipped with overheat protection. The internal design of the motor is designed to protect against leakage and bearing temperature rise.

6) Cylindrical roller bearings and tapered roller bearings are used to bear axial and radial forces;And ensure that the cantilever shaft is very short, reduce the deflection of the shaft, increase the sealing and bearing life, reduce vibration, so that the operation is smooth.

7) Multiple mechanical seals are used to ensure no water leakage in the motor cavity.The oil in the oil chamber, while lubricating the mechanical seal, takes away the heat on the surface of the friction pair of the mechanical seal.

8) The water pumped by the large-flow submersible axial flow pump passes through the motor housing to ensure the cooling of the motor.

Technical parameters of QZ series submersible axial flow pump

Traffic: 450-50000 m3 / h

Head: 1 ~ 24 m

Motor power: 11~ 2000KW

Diameter: 300 ~ 1600 mm

Voltage: 380, V660V, 6KV, 10KV

Medium temperature: ≤50℃